A Romeo? What's That?

Romeo, The Forgotten SiblingThe pre-war Alfa Romeo organisation could be likened in many respects to today's Fiat industrial empire. Although best known for automobiles, the Alfa Romeo product range was diverse and also included commercial vehicles, railway locomotives, buses, trams, tractors and aircraft engines. Only Mercedes Benz could match such a diversity at that time.

Having struggled through the war, with a bombed out factory at Il Portello, Alfa Romeo quickly resumed car production in 1946 assisted by the post-war Marshall Aid program, firstly with a continuation of the 6C2500. However it was already realised that the future lay in volume production and that a new generation of products was required. Equally importantly, the major decision to outsource many components was taken, thus ending an era where virtually the entire product had been designed and produced in-house.

This transformation process was led by Orazio Satta, assisted by his deputies Giuseppe Busso and Giampaulo Garcia, and started with the 1900, the first unitary or monocoque Alfa Romeo, to be soon followed by our beloved Giulietta. As if this was not sufficiently radical, the commercial vehicle range, which consisted of middle range trucks, buses and chassis was to be expanded by offering a new light van and truck range of nominal 1 tonne capacity.

More changes were afoot. From its inception in 1910, every Alfa Romeo product had been assigned a numerical or alphabetical name, such as 20-30, 6C 1500, 430, R.L.... Alfa Romeo products were now to be given a proper name - although project code numbers would continue to be used inside the company. The first new product to be named was the new light van and truck, internal code name tipo dieci or T10, due to be introduced in 1954. Clearly the choice of an original name eluded all concerned as the range was simply called the Romeo! Another departure from the past was that the Romeo was to be left hand drive - all previous Alfa Romeo commercial vehicles having been right hand drive.

The Romeo Autotutto was introduced to the press at the Alfa Romeo Portello (Milan) factory in 1954 and then to the public at the 1954 Turin Motor Show as a panel van and minibus, bearing more than a passing resemblance to the VW Transporter which had already been in production for several years. But there were some marked differences. The Romeo had rear-hinged "suicide" front doors whereas the VW had front hinged doors. The Romeo windscreen was curved and one-piece, while the VW had a V screen of 2 flat glasses. The Romeo had a full height rear loading door, the VW having a top hinged half-door above the engine compartment.

However under the skin all was different, although just as radical as the VW. Engines were either an 1290cc petrol or an 1160cc diesel, but of course, being Alfa Romeo, these were not just ordinary engines... The petrol engine was the new 750 series twin cam destined to power the Giulietta, while the diesel was an 1160cc two stroke twin cylinder with a Roots type supercharger produced under licence from Lizt.

The petrol engine was a detuned version of what would later be installed in the Giulietta Berlina with a single choke Solex carburettor. A compression ratio of 7.5:1 gave 35 bhp and enabled it to run on the low octane petrol generally then available and to carry loads of up to a ton at a top speed of 60mph, more than sufficient for the roads of that day.

There does not appear to be an exact English translation for "Autotutto", it would seem to mean "All Purpose", "Universal" or "Vehicle For All"

On paper, the 30 bhp and 40 mpg given by the diesel engine seemed to be an ideal combination, but more on this later... Transmission was via a four-speed front wheel drive transaxle supplied by ZF and mounted behind the engine.

Suspension was independent all round, front by a transverse leaf spring, rear by trailing arms and transverse torsion bars, tyres were 6.00x16 radials. The chassis was constructed out of well-braced channel section and could take either factory produced van or truck bodies or special bodies produced by other body builders.

Suspension was independent all round, front by a transverse leaf spring, rear by trailing arms and transverse torsion bars, tyres were 6.00x16 radials. The chassis was constructed out of well-braced channel section and could take either factory produced van or truck bodies or special bodies produced by other body builders.

However these features were more than merely technically interesting as they gave the Romeo two notable benefits when compared with the competitors. Firstly, the front wheel drive and transverse torsion bar rear suspension resulted in a large and flat load area which was extremely low at just 35 cms off the ground. Secondly, the wheelbase could easily be extended to accommodate special purpose bodywork, requiring just a "cut and shut" of the chassis longerons and extending the handbrake cable and an hydraulic brake pipe. It is uncertain if such extended chassis versions were actually offered by the factory.

In line with the new policy of buying in many finished components, as well as the ZF transaxle, the Romeo also featured Girling shock absorbers and brakes, Gemmer or Adamant steering boxes, Fabri or Universal front drive shafts and universal joints, Fichel and Sachs clutch and Lucas electrical components.

In line with the new policy of buying in many finished components, as well as the ZF transaxle, the Romeo also featured Girling shock absorbers and brakes, Gemmer or Adamant steering boxes, Fabri or Universal front drive shafts and universal joints, Fichel and Sachs clutch and Lucas electrical components.

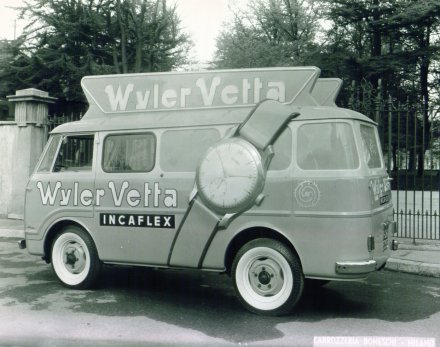

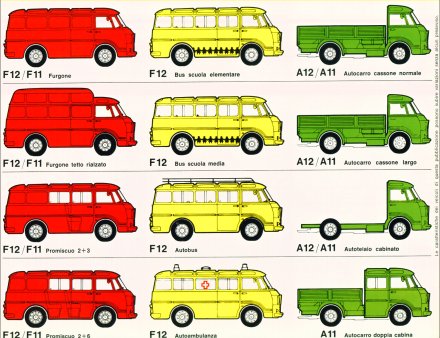

"Autotutto" can be literally translated as "all purpose" and to this end Alfa Romeo themselves offered an amazingly wide variety of standard factory produced bodies. The standard van body offered very easy access to the load area through a single side-hinged rear door and a single or optional double side doors on the passenger (pavement) side. The range included van, high roof van, "Promiscuo" (van with additional side windows and rear seating), minibus, school bus, ambulance, pick-up, drop-side truck and double cab truck. Many carrozzerie (coachbuilders or bodybuilders), Boneschi and Colli to name just two, produced specialist bodies such as a mobile shops and clinics. Many examples of these can be seen in the "Carrozzerie" section of this website.

Alfa Romeo was state owned at this time and the Romeo found a ready market with the police, military and other government bodies, possibly as a result of political pressure to buy in-house and not to spend "real money". The typical buyer of a small van or truck, be it market trader, baker or builder, found it difficult to afford the relatively expensive Romeo and so tended to choose the Fiat equivalent instead. Despite this, there were many unusual commercial applications of the Romeo, as shown in the accompanying photographs.

Alfa Romeo was state owned at this time and the Romeo found a ready market with the police, military and other government bodies, possibly as a result of political pressure to buy in-house and not to spend "real money". The typical buyer of a small van or truck, be it market trader, baker or builder, found it difficult to afford the relatively expensive Romeo and so tended to choose the Fiat equivalent instead. Despite this, there were many unusual commercial applications of the Romeo, as shown in the accompanying photographs.

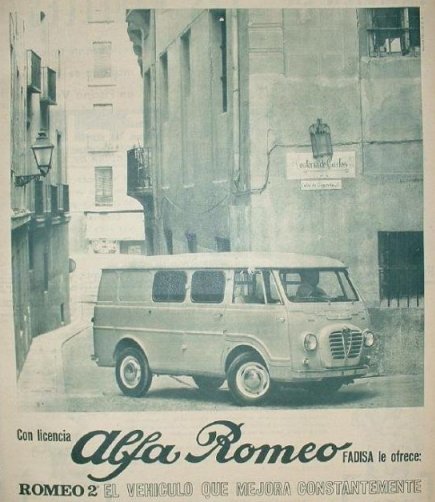

The Romeo Autotutto was updated to become the Romeo 2 in 1957, yet there is no evidence of any significant changes to be found!

The final version, essentially the Romeo 3, was introduced in 1966, but the name reverted to just Romeo. This incorporated some changes destined for the forthcoming F12 & A12, including hydraulic clutch operation & an adjustable driver's seat. The Romeo 3 had a production run of only some 6 months or so before being replaced by the Giulia 1300 engined F12 and A12 models. In all, some 23,000 Romeos had been produced between 1954 & 1966.

Abandoning the use of a model name, "F" depicted a furgone, or van, "A" depicted an autocarro or light truck, while "12" indicated the carrying capacity of 12 quintale (1 quintale = 100kg). The F12 and A12 featured a face-lifted Romeo cab or body, with a centre grille similar to that of the Giulia Super, together with conventional front-hinged cab doors and a new dashboard. The Giulia parts bin had clearly been raided - easily recognisable are the Giulia fuel filler flap used to access the radiator filler cap, interior door handles & heater controls.

The chassis was basically as that of the Romeo, although ATE front disc & Bendix rear drum brakes were fitted in place of the earlier Girling units, together with a de-tuned version of the Giulia 1300 ti engine, a new Oto-Melara transaxle and supposedly improved driveshafts. There were also lower load capacity versions with marginally lower output engines to take advantage of reduced taxes for city use, these were called the F11 and A11, with a load capacity of 11 quintale (1100kg). While the Romeo was normally available in just one wheelbase, these new models were also offered as a chassis/cab with a longer wheelbase. A Perkins diesel engine was later offered as an option, no doubt due to the particularly low price of diesel in Italy.

The final version, essentially the Romeo 3, was introduced in 1966, but the name reverted to just Romeo. This incorporated some changes destined for the forthcoming F12 & A12, including hydraulic clutch operation & an adjustable driver's seat. The Romeo 3 had a production run of only some 6 months or so before being replaced by the Giulia 1300 engined F12 and A12 models. In all, some 23,000 Romeos had been produced between 1954 & 1966.

Abandoning the use of a model name, "F" depicted a furgone, or van, "A" depicted an autocarro or light truck, while "12" indicated the carrying capacity of 12 quintale (1 quintale = 100kg). The F12 and A12 featured a face-lifted Romeo cab or body, with a centre grille similar to that of the Giulia Super, together with conventional front-hinged cab doors and a new dashboard. The Giulia parts bin had clearly been raided - easily recognisable are the Giulia fuel filler flap used to access the radiator filler cap, interior door handles & heater controls.

The chassis was basically as that of the Romeo, although ATE front disc & Bendix rear drum brakes were fitted in place of the earlier Girling units, together with a de-tuned version of the Giulia 1300 ti engine, a new Oto-Melara transaxle and supposedly improved driveshafts. There were also lower load capacity versions with marginally lower output engines to take advantage of reduced taxes for city use, these were called the F11 and A11, with a load capacity of 11 quintale (1100kg). While the Romeo was normally available in just one wheelbase, these new models were also offered as a chassis/cab with a longer wheelbase. A Perkins diesel engine was later offered as an option, no doubt due to the particularly low price of diesel in Italy.

Later versions of the F12 & A12 featured a full width plastic grille, more plushly trimmed door panels, together with instruments & a rake adjustable steering column based on those used in the Alfasud, the F12 also used Alfasud Giardinetta rear lights.

Few factory records remain, although it is believed that the total production of all A11, A12, F11 & F12 was around 17,300 units.

The Romeo 2 & F12 ranges was also produced in Spain by Fadisa (Fabricacion de Automoviles Diesel SA) under licence from Alfa Romeo. The vans were a common sight on Spanish roads in the 1960s and 1970s. There is a fascinating period film of the Fadisa assembly lines here on You Tube. Fadisa was later bought by Ebro which facelifted the F12 into the Ebro F108. Ebro versions were only offered with the Perkins diesel engine & differed from the Alfa Romeo models in that they retained drums brakes & featured rectungular headlamps & a particularly ungainly looking centre dashboard console. See here for the Ebro promotion film. Yet another example of an unsuccessful mid-life facelift? Ebro was in turn bought by Nissan whereupon the F12 series appears to have been finally discontinued.

Ital Design produced a proposal for a New York yellow cab or taxi which was shown at the New York Museum of Modern Art in 1976. Perhaps surprisingly, this was based on the F12, yet on reflection the F12 mechanical package was ideal in that it was readily available, front wheel drive, front & rear independant suspension & a low floor height. Some 16 years later it returned to be one of 32 vehicles exhibited as part of "Italian Avantgarde in Car Design" in Manhattan in 2002.

So, what is the Romeo Autotutto like to look at and to drive? "Quirky" springs to mind. Giulietta owners will immediately recognise the Giulietta Spider and Sprint chrome centre grille on the nose of the Romeo, and even the front lights are as fitted to some Giuliettas. Above the nose is a hinged ventilation flap on which is mounted "Romeo" or "Romeo 2" in small cast letters. The final Romeo 3 version had a large chromed Romeo script, in the style of the flamboyant pre-war full Alfa Romeo logo. Opening the rear-hinged door to enter the cab, one sees that the door panel has "Romeo" embossed in large letters, just in case one forgets what model it is!

Climbing into the driver's seat, the speedometer can be readily seen through the steering wheel, with Giulietta type electrical switches on either side. But the speedometer is not just an ordinary one picked from the Veglia catalogue, it has the Alfa grille shape embossed into the face. Clearly they really do want you to know what you are driving! Across the dashboard is a chrome plated cover to the fusebox, matched by a similarly styled ashtray, and Giulietta Spider owners will recognise the heater.

temperature gauge indicates that this is a diesel version.

Starting the engine is straightforward, although it takes a while for the 750 type fuel pump to prime the carburettor. The engine is in the cab between the driver and passenger footwells, but it is hardly audible thanks to the very effective sound proofing of the cover. The gear lever is conveniently at hand beside the seat. Handbrake off, and the little engine pulls away, very few revs being required considering the size and weight which it is pulling. Gear changes are slower than on a Giulietta but easy, reverse is safely well out of the way. Steering is somewhat heavy when parking or manoevering, but soon lightens when under way, and the brakes are firm and reassuring. The Romeo pulls well in 3rd and 4th gear, 1st is rarely used except when moving off. Not as bad as one might have expected from a 50 year old van...

As for today, few Romeo Autotuttos have survived, estimates vary at between 30 and 100 examples, with not many being in a roadworthy state. Those that are still in existence have some amazing bodywork. Since becoming interested in Romeos in the late 1980s, I have seen or heard of an enormous furniture van, ambulance, blood donor clinic, long wheelbase car recovery truck, street light maintenance truck, and an armoured bullion van.

The later A12 and F12 are more common and have recently become in demand as service vehicles for historic race and rally teams etc, but how practical are they for serious work where reliability is a prime requirement?

The Romeos suffer from the usual body corrosion problems, hardly surprising considering their age and the total absence of rust protection. However the separate sturdy chassis seems to survive very well. The Giulietta engines and ZF transaxles are long lived, and suspension and steering condition is according to whether the assemblies have been regularly greased, in common with the Giuliettas. The main weakness of the Romeo is reputed to be with the driveshafts and universal joints. Treat them kindly and they last, but it is suggested by some that hard use, or the increased torque imposed by fitting a 1750 engine (once a popular conversion), can be the end of them. Watch this space for recent experiences!

And the Romeo diesels? After many conversations with those in the know in Italy, just one surviving diesel engined Romeo has been heard of. They seem to have quickly gained a reputation of being slow and unreliable and were soon replaced by the fitting of a 750 or later 101 series petrol engine. All that is usually left is the water temperature gauge in the centre of the dashboard.

I am often asked what is the appeal of the Romeo. Maybe it is the concept of a van powered by a twin cam motor, or the advanced design concept - compare the Romeo with the then current equivalent offerings of Ford or Austin. Perhaps it is just that I bought one in a weak moment and just don't want to part with it. So please do come and have a chat if you see me at a Giulietta Register meeting with my Romeo 2 Autoambulanza, you cannot miss it, it is the one with the siren & blue lamps...

Ten interesting, unusual or useless Romeo facts...

1/ The fact that the Romeo ever existed!

2/ The Romeo was one of the first mass production light commercial vehicles to be front wheel drive & to be specifically designed to use radial tyres, the Citroen H van being the first.

3/ At least one prototype Romeo was built with conventional front hinged cab doors, while production versions had rear hinged "suicide" cab doors, a strangely retrograde step.

4/ All Alfa Romeo cars of the period used LH thread wheel studs & wheel nuts on the left, whereas the Romeo used RH thread studs & nuts on all wheels.

5/ The Romeo centre grille was also used on the Giulietta Spider & early Giulietta Sprints & saloons.

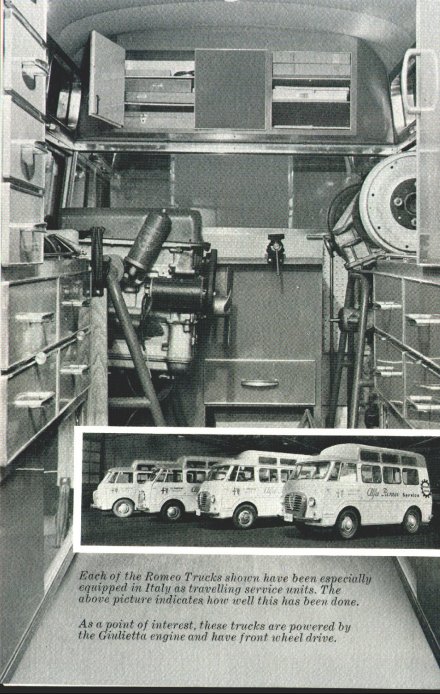

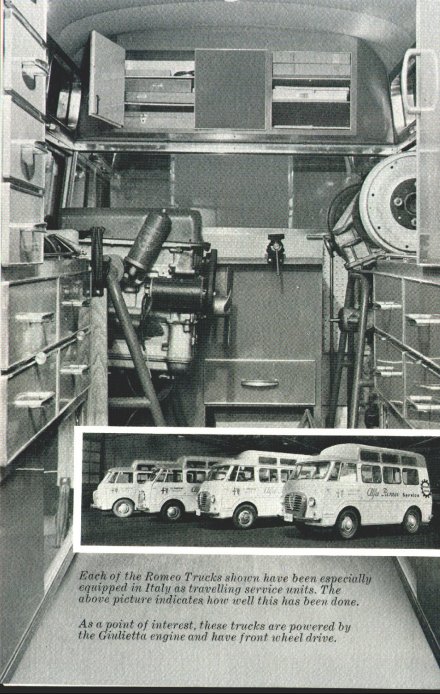

6/ Alfa Romeo Inc., the factory owned US importer, commisioned the production in 1960 of a fleet of 5 Romeo vans to be converted into mobile training workshops to tour the US dealer network. Despite being imported into the US on a special temporary basis due them not having U.S. DOT approval, 4 of the 5 have survived, 2 of which are now back in Europe. The fifth van is believed to have been totalled in an accident in the 1960s or 1970s.

7/ Many F12 ambulances were still owned by the Italian military until the early 2000's. Some have been released from storage for sale with milages often below 10,000 miles.

8/ Scattilini's A12 car transporter could be ordered with a towbar for towing a trailer for another car. 1300cc pulling 2 cars AND a trailer!

9/ Fadisa of Spain, who built both the Romeo & F12/A12 under licence, exported a large number to Columbia in South America. It is variously reported that the production line was moved there in around 1965 but no firm evidence of this has been seen & production continued in Spain for many years...

10/ The Romeo & F12/A12 were the first & only light van & truck range to be designed & produced in-house by Alfa Romeo.

1/ The fact that the Romeo ever existed!

2/ The Romeo was one of the first mass production light commercial vehicles to be front wheel drive & to be specifically designed to use radial tyres, the Citroen H van being the first.

3/ At least one prototype Romeo was built with conventional front hinged cab doors, while production versions had rear hinged "suicide" cab doors, a strangely retrograde step.

4/ All Alfa Romeo cars of the period used LH thread wheel studs & wheel nuts on the left, whereas the Romeo used RH thread studs & nuts on all wheels.

5/ The Romeo centre grille was also used on the Giulietta Spider & early Giulietta Sprints & saloons.

6/ Alfa Romeo Inc., the factory owned US importer, commisioned the production in 1960 of a fleet of 5 Romeo vans to be converted into mobile training workshops to tour the US dealer network. Despite being imported into the US on a special temporary basis due them not having U.S. DOT approval, 4 of the 5 have survived, 2 of which are now back in Europe. The fifth van is believed to have been totalled in an accident in the 1960s or 1970s.

7/ Many F12 ambulances were still owned by the Italian military until the early 2000's. Some have been released from storage for sale with milages often below 10,000 miles.

8/ Scattilini's A12 car transporter could be ordered with a towbar for towing a trailer for another car. 1300cc pulling 2 cars AND a trailer!

9/ Fadisa of Spain, who built both the Romeo & F12/A12 under licence, exported a large number to Columbia in South America. It is variously reported that the production line was moved there in around 1965 but no firm evidence of this has been seen & production continued in Spain for many years...

10/ The Romeo & F12/A12 were the first & only light van & truck range to be designed & produced in-house by Alfa Romeo.

Tony Stevens, proprietor of AlfaStop

This article is largely based on one which originally appeared in the Giuliettaetta #76, the quarterly newsletter of the Giulietta Register.

copyright Tony Stevens 2015

This article is largely based on one which originally appeared in the Giuliettaetta #76, the quarterly newsletter of the Giulietta Register.

copyright Tony Stevens 2015